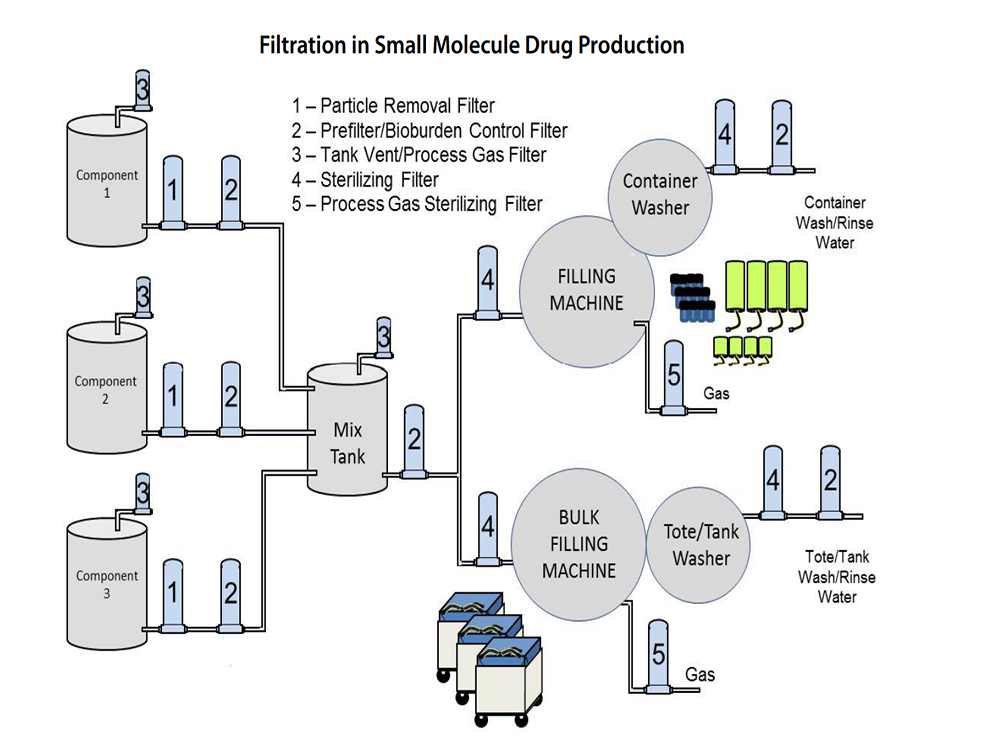

Filtration in Small Molecule Drug Production

Zhehan Filter Equipment Company has rich acknowledge and experiences in bio-pharmaceutic filtration systems. We can design and produce stainless tanks, solvent inlet strainer and all key parts of filters in the whole filtration systems.

We customized stainless filters and filter elements for our customer who are involved in Filtration in Small Molecule Drug Production through the year of 2020.

Filtration in Small Molecule Drug Production

- Particle Removal Filter

- Prefitter/Bioburden Control Filter

- Tank Vent/Process Gas Filter

- Sterilizing Filter

- Process Gas Sterilizing Filter

Small molecule pharmaceuticals are usually produced using a chemical process. These processes are very different from the cell-based processes used to make biopharmaceuticals (covered in a separate Selection Guide). In both cases, filters are used to protect the processes and product at almost every step.

The schematic below is a very simplified representation of the steps in the processes used to formulate and package a small molecule drug. Several of these steps may be repeated in support of individual processes or between processes, but the basic functions and types of filters used for those functions are similar no matter where the filters are located in the facility.

There are 4 process areas where filtration is used. First is for contaminant removal in the ingredients feeding each process. Second, controlling the amount of bioburden during the process. Third, preventing environmental (airborne) contaminants from reaching the intermediate products or final product while in storage tanks or removing contaminants from any process gases that might be used. Fourth, and most critical, is sterilizing filtration of the final product just before packaging.

Address

Address  Email

Email  Phone

Phone