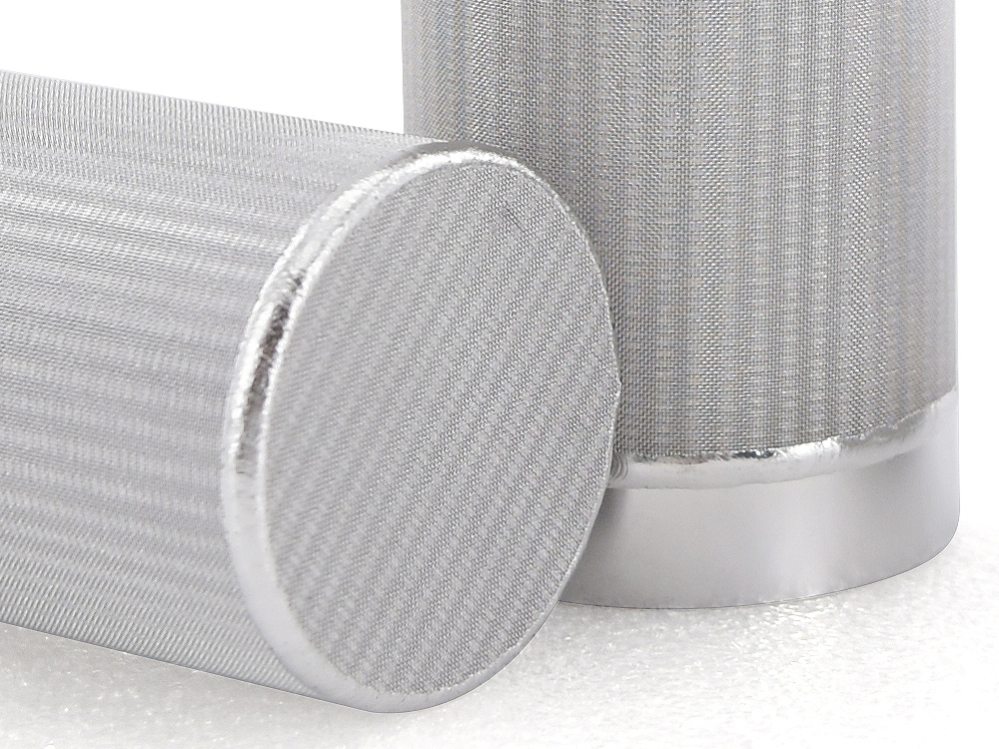

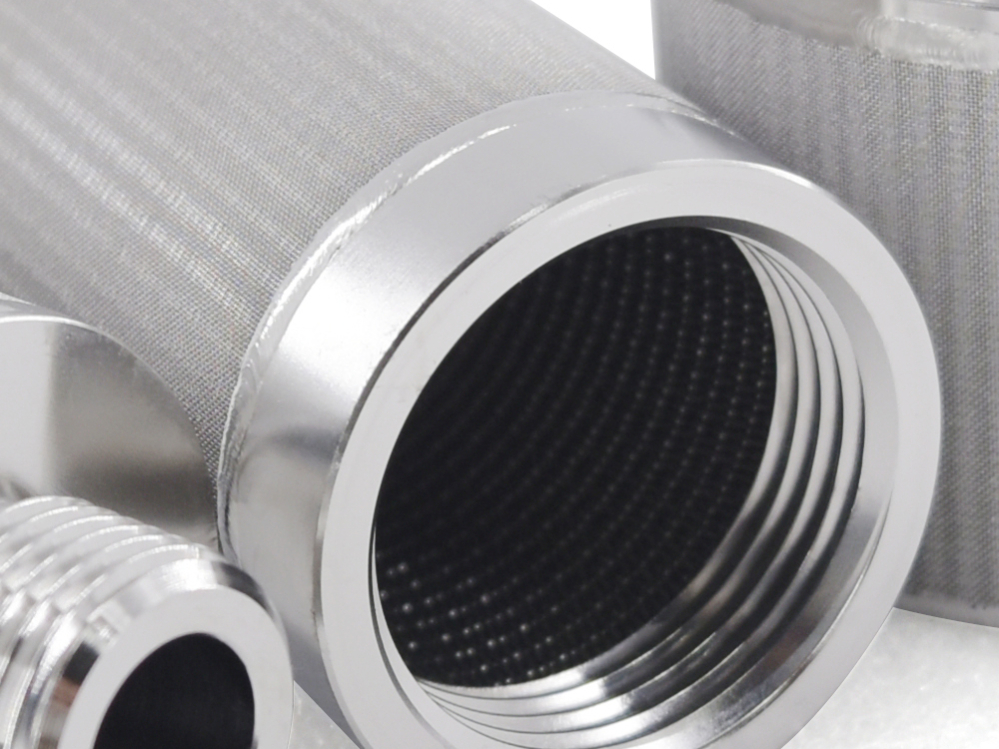

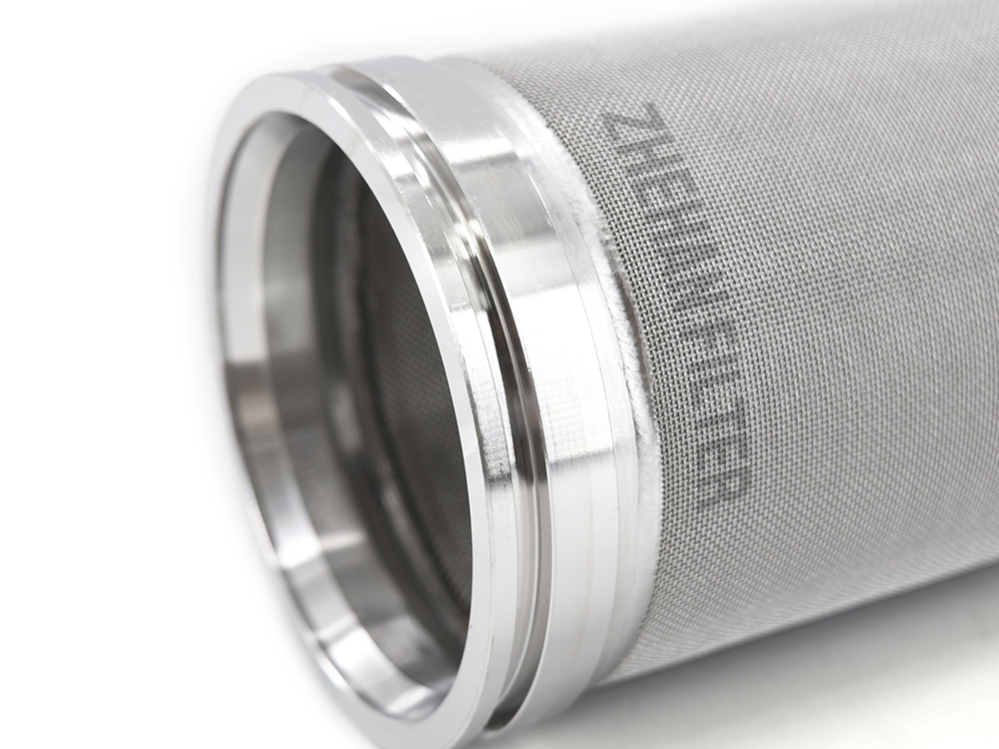

Stainless Steel Sintered Mesh Filter Caitridge Element With Diffrent Connectors 5

Description

Sintered Mesh Screen Filter Cartridge Material: stainless steel 304, 304L, 304HC, 316, 316L, 321,430 or as per your request. Application: The filter has been widely used in transformer oil, turbine oil, hydraulic oil, aviation kerosene, petroleum, chemical, power plant, coal carbon, mining, pharmaceutical, food, and engineering industries. Customers can also avail customized sintered bronze filter cartridges, which are used mainly for liquid oxygen, compressed air and silencing with a filtration efficiency of 5 to 50 micron. read more- Price

Description

Related Products

91 Customized SUS304 316 316L Stainless Steel Sintered Mesh Filter Caitridge Element

stainless suction filter

93 Customized 304 Stainless Steel Five-layer Sintered Mesh Filter Cylinder Injection Molding Oil 60um

Address

Address  Email

Email  Phone

Phone