-

Address

Address -

Email

Email -

Phone

Phone

- Home

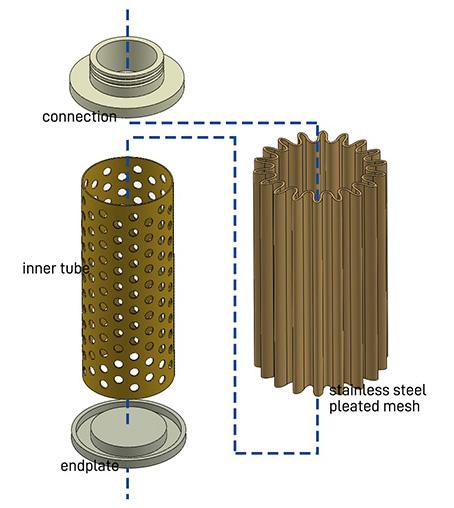

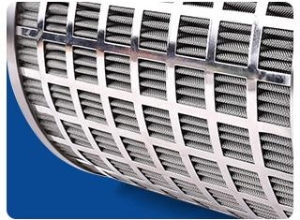

- 1Pleated filter

Error: Contact form not found.